Questions? : Call 1800 121 4415 (Monday to Saturday 10AM to 6PM)

Water Ionizer Cleaning Systems: Why DARC II is the best.

We drink alkaline water to enjoy the profound benefits created from the transformation of water through created through electrolysis – or more loosely “ionization”.

Here is the situation: Water has minerals. Minerals build up on the electrodes and membranes and these are the two components in your water ionizer that transform the water. Scale essentially “coats” these components, compromising their ability to transform the water. This mean a decrease in pH, ORP and H2 performance, which in turn, reduces any benefit you receive from the water - precisely what you bought your ionizer for in the first place.

All ionizers have cleaning systems, but all cleaning systems are not created equal. Most ionizers employ outdated systems that have been around for years without any advancement or technological improvement.

Smart Shopper's Shortcut

Smart Shopper's Shortcut What you need to know about ionizer cleaning systems...

Before you buy an ionizer, it is crucial that you understand what type of cleaning cycle it employs. This is one of the most important considerations because it determines how well your ionizer will perform over the long haul. If you are shopping around, ask about the type of cleaning system and how it works. If all the salesperson can do is quote a gimmicky cleaning system name, but can’t tell you the specific acidic to alkaline ratio in their system, or tell you specifically how it works…run. Fast! Then call us. We’ll tell you precisely how DARC II works and why it is the best ionizer cleaning system available.

The DARC Advantage.

AlkaViva set a new industry standard in 2006 when it launched the patented Dual Automatic Reverse Cleaning system (USA Patent No. 6,951,225). DARC was, and still is - thanks to the patent protection - revolutionary because it cleans with every use, eliminating damaging scale buildup. It accomplishes this by reversing polarity each time you use the ionizer.

The revolutionary DARC cleaning system eliminates mineral scaling on the electrodes – protecting your investment and ensuring years of healthy water from your ionizer. DARC is highly effective because it works in the background to clean your electrode, each time you use your ionizer and while you are actually using it. The result is a vastly improved acidic to alkaline cleaning ratio, which is critical to keeping the electrodes cleaner than other systems that offer a 15:1 ratio or a 30:1 ratio. The Enagic™ SD501 which retails at almost $4000, only cleans using a 30:1 ratio1. The importance of this breakthrough cannot be understated.

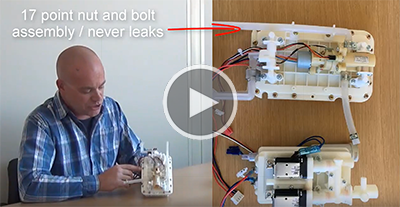

Additionally, with the dual solenoid system that directs water flow (actually what is patented and what DARC refers to), you never have to wait while your ionizer cleans to get your alkaline water – an industry first! Our Athena Classic and Delphi models employ DARC cleaning.

The Best just got Better: the New and Improved DARC II.

AlkaViva once again sets a new industry standard by launching DARC II in its new H2 Series. Over the 11 years since we released DARC we have learned a few things and consequently saw how it could be substantially improved. DARC II offers you the same highly effective cleaning as the original DARC, and convenience of never waiting, but now gives you increased durability.

Because the original patented DARC solenoid system is outside the water cell, the solenoids DO NOT benefit from the acidic cleaning. The electronic solenoids in DARC contain a metal actuator that operates on a very tight tolerance. Once it gets even a hint of scale, it becomes susceptible to failure. Over 11 years since we launched DARC this was not an uncommon issue in hard water areas.

We improved DARC II by eliminating the electronic solenoid containing the metal actuators. We eliminated the potential failure of the electronic solenoid and also now employ a mechanical ceramic valve (replacing actuator) that is 100% resistant to any scaling. We did not stop there. Reversing the polarity each time you used the ionizer did not in reality create the best possible acidic to alkaline ratio – which would be 1:1. Imagine you fill an 8 oz glass, then one liter, then a 16 oz glass, then a gallon and on and on. You don’t come close to a 1:1 ratio – even over the life of the ionizer. We now reverse the polarity every 5 liters – which creates a ratio much closer to 1:1, thus improving the effectiveness.

DARC II is the new standard in on-board ionizer cleaning systems borne of experience and research and development. Another AlkaViva first.

Reverse Polarity Cleaning.

Each electrode in your ionizer has either a positive or negative polarity. Reverse polarity cleaning is simply when your ionizer reverses the polarity; positive electrodes become negative and conversely. When an electrode is “bathed” in alkaline water containing scaling minerals, it becomes susceptible to scaling. When the polarity is reversed, the same electrode is now exposed to acidic water which removes the scale.

All water ionizers clean using reverse polarity. However, the cleaning systems differ radically in how they trigger it, the interval at which they perform the cleaning cycle, and most importantly, how effective they are.

Understanding other Cleaning Systems.

Since it is the acidic water which eats away the scale, for optimal efficacy the cleaning cycle must feature a good “acid to alkaline cleaning ratio”. The more acidic water that is run to bath the electrodes the cleaner they remain and the greater their performance and longevity.

The way a water ionizer is “programmed” to clean is crucial in determining the cleaning ratio. The most common systems have been in use many years without improvement:

- Manual system: you must remember to reverse the polarity and initiate the cycle yourself.

- Timer system: cleans at a set-interval, such as every 15 minutes of use. After 15 minutes of run time, the next time you turn the ionizer on, the unit starts the cleaning cycle. Most often you must wait while it completes the cycle.

- Volume system: Similar to the timer system, but cleans based on a set volume of water (Say for example 10 gallons) passing through the ionizer. You must also wait.

- Post cleaning systems: while they clean after each use, the clean cycle is extremely short resulting in a poor acidic to alkaline ratio. They also use a finite amount of water to clean – only the water that is in the cell (since the cleaning is triggered after the ionizer is shut down). The better post-use systems drain the cell when the cycle is complete, so you do not have contaminated water in the cell that will expel into the drinking water when the ionizer is turned on. These draining systems are prone to failure at both the PCB and drain valve level.. Not as robust, effective or durable as DARC.

Each has its draw backs: you can forget to trigger a manual cycle, the timer and volume systems have poor acidic to alkaline cleaning ratios. The worst drawback is that with each of the above systems you have to wait for the cycle to complete before you can receive alkaline drinking water.

In summary, we love that you have read this far! Because now you can see – emphatically – why cleaning is so important and why and how AlkaViva’s H2 Series with its new and improved DARC II is your best choice. Consider your searching over!

1) The SD501 cleans for 20 seconds for each 10 gallons of use. It would take the Enagic ionizer approximately 10 minutes of run time at 1 gpm flow rate to produce 10 gallons. Therefore, 10 mins X 60 seconds = 600. The cleaning ratio is then 600:20 or reduced is 30:1.